Material: matter with a particularly useful set of properties

Material Research and Development

Services

About me

Luciano Avila Gray, M.Sc.

I am a passionate materials scientist with experience ranging from scientific research to industrial application.

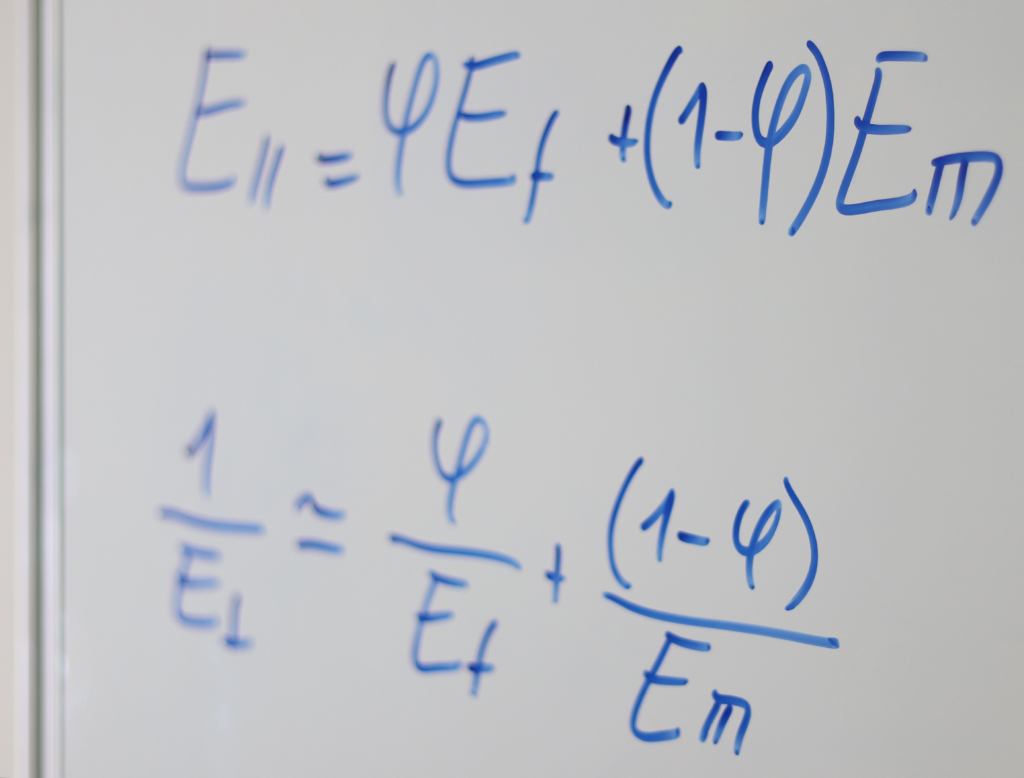

My qualifications allow me to relate atomic and crystalline structures with material properties and comprehend the effects of the manufacturing processes on the microstructure. I have extensive experience in characterization at both, the micro and macro levels, using a wide range of techniques including microscopy, diffraction, spectroscopy, thermal analysis, and mechanical testing.

Between 2013 and 2024, I occupied leading positions at the Chair of Carbon Composites of the Technical University of Munich, where I supervised and guided more than a dozen research associates in their research and Ph.D. projects.

Some of the topics were: developing and optimizing manufacturing processes, online process monitoring, material characterization, simulation, and additive manufacturing.

I have also been in charge of numerous direct industry contracts.

I am a passionate materials scientist with experience ranging from scientific research to industrial application.

My qualifications allow me to relate atomic and crystalline structures with material properties and comprehend the effects of the manufacturing processes on the microstructure. I have extensive experience in characterization at both, the micro and macro levels, using a wide range of techniques including microscopy, diffraction, spectroscopy, thermal analysis, and mechanical testing.

My qualifications allow me to relate atomic and crystalline structures with material properties and comprehend the effects of the manufacturing processes on the microstructure. I have extensive experience in characterization at both, the micro and macro levels, using a wide range of techniques including microscopy, diffraction, spectroscopy, thermal analysis, and mechanical testing.

Between 2013 and 2024, I occupied leading positions at the Chair of Carbon Composites of the Technical University of Munich, where I supervised and guided more than a dozen research associates in their research and Ph.D. projects.

Some of the topics were: developing and optimizing manufacturing processes, online process monitoring, material characterization, simulation, and additive manufacturing. I have also been in charge of numerous direct industry contracts.

Between 2013 and 2024, I occupied leading positions at the Chair of Carbon Composites of the Technical University of Munich, where I supervised and guided more than a dozen research associates in their research and Ph.D. projects.

Some of the topics were: developing and optimizing manufacturing processes, online process monitoring, material characterization, simulation, and additive manufacturing.

I have also been in charge of numerous direct industry contracts.

Research associate at the Chair of Carbon Composites of the Technical University of Munich

Materials Engineer at the Argentinian Commission of Atomic Energy (CNEA)

Master in Materials Science from the universities TUM, LMU, Rennes and Torino

Materials Engineering at the Institute of Technology

“Jorge Sabato”, Buenos Aires, Argentina

A material’s composition and microstructure are shaped during manufacturing and directly determine its properties

Unlocking the Material´s Potential

I offer a generalist approach to materials research and engineering covering its development, characterization and degradation as well as process development and optimization.

The collaboration can be flexibly adapted to your needs, whether as an independent contractor, as part of your team for the duration of an internal development project, or as a sub-contractor for a specific work package.

I can also be a qualified and valuable companion in publicly funded research projects.

Areas of work

Guiding Small Business towards Higher Performance

Many industries and manufacturers could improve if they had access to the appropriate characterization methods.

For that reason, I offer affordable and streamlined mechanical testing, aimed in particular at small businesses.

One of the most used methods is bending, due to its low cost and easy sample preparation, setup, and speed. It is a very convenient benchmark used to compare properties, optimize processes, and for quality control.

Other test methods up to 2500N are also offered.

Tensile test setup of a 3D Printed PLA sample

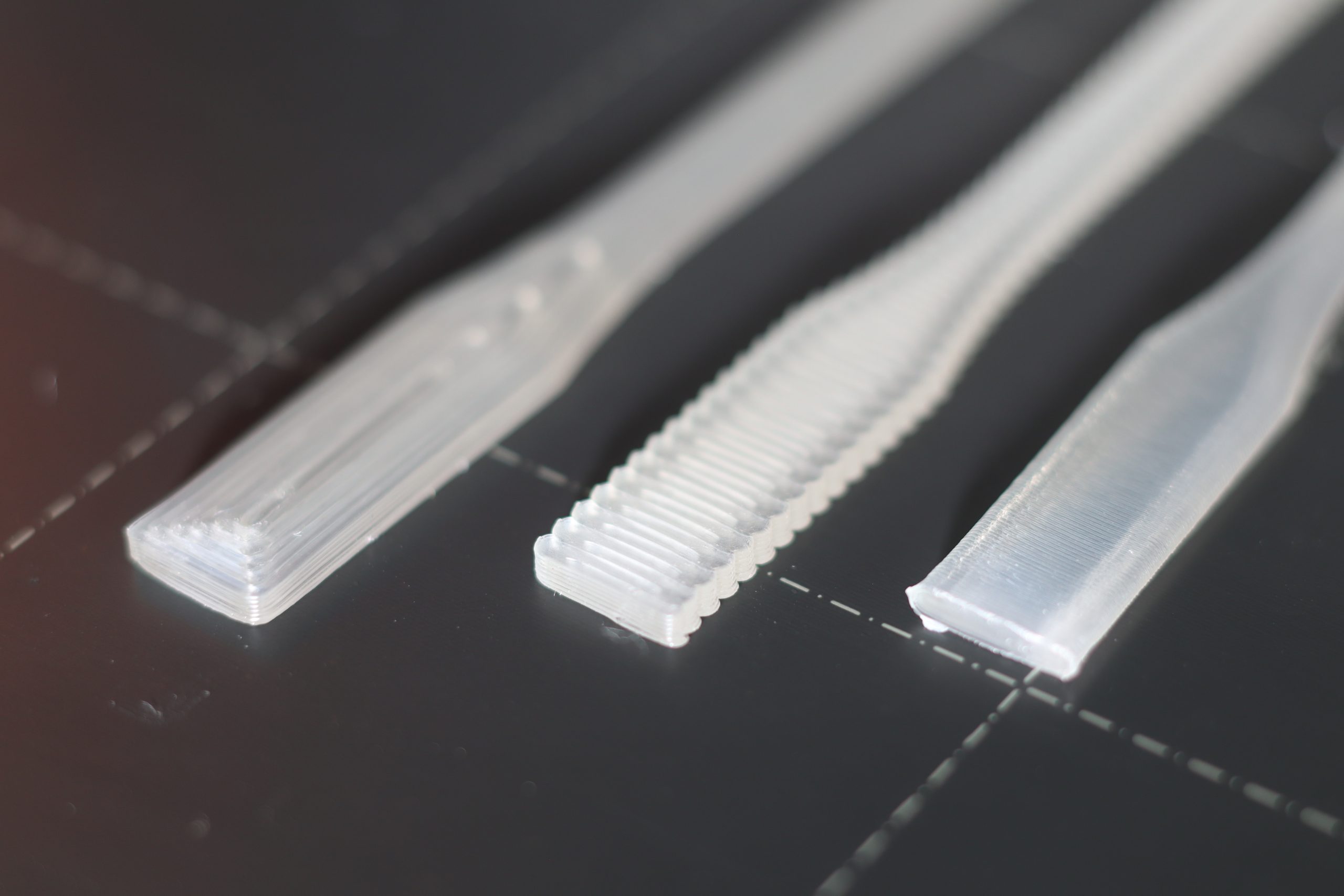

DIN 527-4 Type B coupons 3D printed in the three main directions. Every print direction produces different structures and properties.

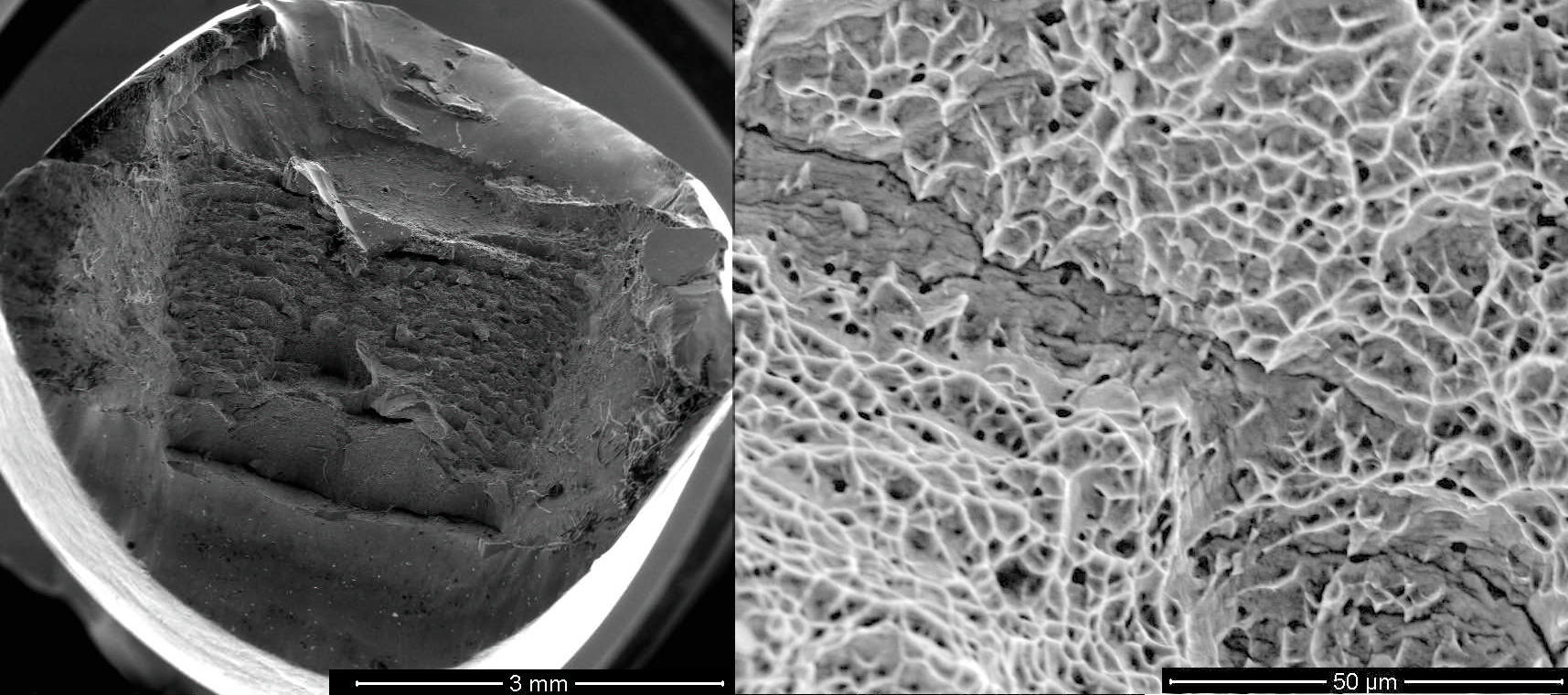

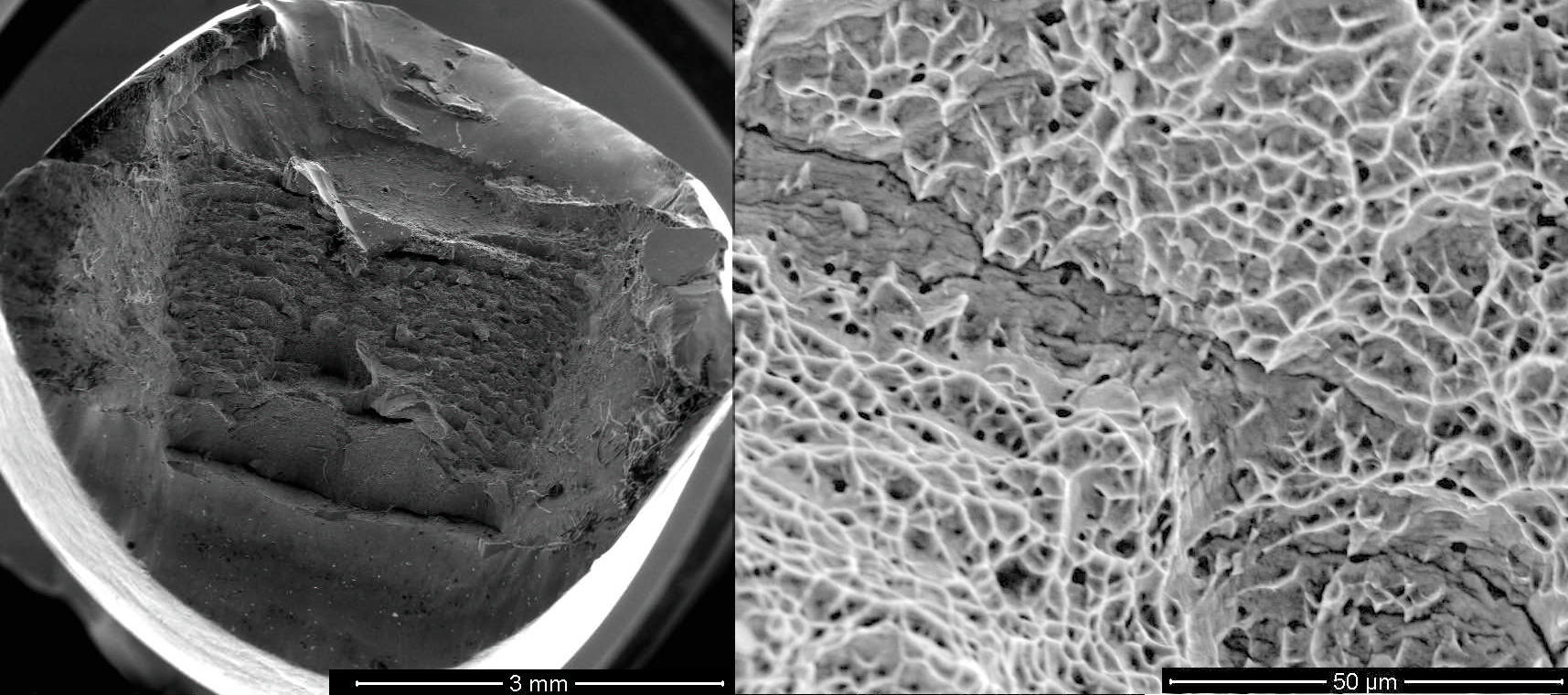

Scanning Electron Microscopy (SEM) is a very useful technique for fracture analysis.

The mechanical behavior of plastics is usually discribed with several viscoelastic parameters. They can be determined using creep, relaxation and oscillatory DMA test.

Material properties like glass and melting temperatures, crystallinity or degree of cure can be measured with Dynamic Scanning Calorimetry (DSC) and used to optimize process parameters.

Characterization Campaigns

Expert Support in Multi-Level Characterization

Some questions cannot be answered solely by examining a material’s mechanical properties. A broader perspective, achieved by applying different techniques, can often better explain the underlying causes.

I offer one-stop characterization services in cooperation with partner institutes.

Characterization Campaigns

Expert Support in Multi-Level Characterization

Some questions cannot be answered solely by examining a material’s mechanical properties. A broader perspective, achieved by applying different techniques, can often better explain the underlying causes. I offer one-stop characterization services in cooperation with partner institutes.

Scanning Electron Microscopy (SEM) is a very useful technique for fracture analysis.

The vicoelastic behavior of polymeric is usually discribed with several viscoelastic parameters. They are determined using creep, relaxation and oscillatory DMA test.

Material properties like glass and melting temperatures, crystallinity or degree of cure can be measured with Dynamic Scanning Calorimetry (DSC) and used to optimize process parameters.

Training

Custom Training in Materials Science, Composites, and Characterization

The courses can be designed to fit your needs with regards to subject, depth, duration, and format (presential, online, hybrid, or workshop). Here are some of the possible subjects:

Contact

Feel free to get in touch to discuss your needs or explore how I can support your project. Whether you’re looking for training, testing, or research collaboration, I’m here to help with flexible, customized solutions.

Telephone: +49 (0) 1573 8811 203 / e-Mail: engineering@avilagray.com

Telephone: +49 (0) 1573 8811 203

e-Mail: engineering@avilagray.com

I do not claim the title of “Engineer,” as I currently do not meet the formal requirements under the “Bavarian Law on the Protection of the Professional Title Engineer” (BayIngG). The authorization is presently in process.